- Home

- »

- SURFSHAPER®

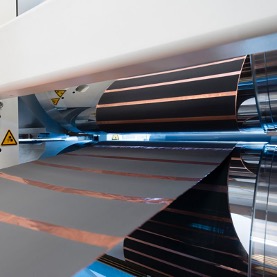

SURFSHAPER® BATTERY ELECTRODE MANUFACTURING INLINE QUALITY INSPECTION

Surface Defect INLINE 100% quality Inspection helps ensure reduction of scrap and increases safety of battery production in gigafatories.

DESCRIPTION

The different manufacturing processes used for cilindrical, pouch, and prismatic battery cells are safer with a Lazpiur turnkey quality Inspection solution based in Stereophotometric own technology. The different processes can be monitored and inspected:

- Electrode Application (pre or post calendering)

- Separator Production

- Solid State Coating

- Fuell Cell Coating

INFORMATION

- Scalable Solution based in the roll’s width

- Flexible location available

- High Speed Process Time

- Stereophotometric Technology developed by Lazpiur

- Flexible Software.

- Deep Learning Module Available.

- Standard solution which can fit with an existing machine or new machine

- Potential defect to be detected:

-

- Decarburization

- Cracks

- Wrinkles

- Air Bubbles

- Dark Points

- Craters

- Holes

- Tape Splicing

- Non continuity

- Marking in Al-Cu (laser or ink available) as optional for traceability.

- Standard information cannel for process monitoring

- Defective Analysis included.

- Traceability control and integration to factory control layers.